Are you ready to dive into the world of sublimation sticker paper? In this comprehensive guide for 2023, we explore everything you need to know about choosing and using this versatile medium. From understanding different types of paper to mastering the sublimation process, we provide expert tips and techniques to help you create stunning, long-lasting stickers. Unleash your creativity and take your designs to the next level with sublimation vinyl sticker paper!

Today, we shall learn:

Part 1: What is a Sublimation Sticker Paper?

Part 2: How to use sublimation sticker paper?

Part 3: Best sublimation sticker paper recommendations

Part 4: Summary and FAQs

Part 1: What is a Sublimation Sticker Paper?

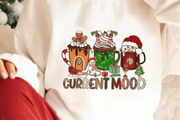

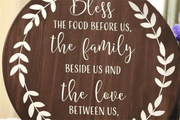

Sublimation sticker paper is a specialized type used in the sublimation printing process. Sublimation printing involves transferring ink onto various materials using heat and pressure, producing vibrant and long-lasting prints. Sublimation sticker paper is specifically for creating stickers or decals with sublimation inks.

One key difference between sublimation sticker paper and vinyl sticker paper is the printing method. Sublimation printing uses heat-activated sublimation inks, allowing the ink to penetrate the surface of the paper and bond with the material being printed on. This results in durable, vivid prints resistant to fading, peeling, or scratching.

On the other hand, sublimation vinyl sticker paper is for use with inkjet or laser printers. It typically has an adhesive backing and a printable vinyl surface. Vinyl sticker paper is commonly helpful for creating stickers, labels, or decals on walls, laptops, or car windows. The ink used in vinyl sticker printing sits on top of the paper, creating a layer susceptible to wear and tear over time.

Another important distinction is the compatibility with different materials. Sublimation sticker paper is for sublimation-compatible materials such as polyester fabric, ceramic, or metal. The heat-activated sublimation inks bond with these materials at a molecular level, resulting in vibrant and permanent prints. In contrast, vinyl sticker paper works on a broader range of surfaces, including glass, plastic, cardboard, and more.

In summary, sublimation sticker paper can produce highly durable, vibrant, and long-lasting prints when used with compatible materials. Sublimation vinyl sticker paper, on the other hand, is more versatile in terms of the surfaces it can apply to; however, the durability of the prints may vary depending on the quality of the adhesive and ink used.

Part 2: How to use sublimation sticker paper?

Using sublimation sticker paper allows you to create vibrant and durable stickers for various applications if you follow these steps effectively:

Step 1: Design Preparation

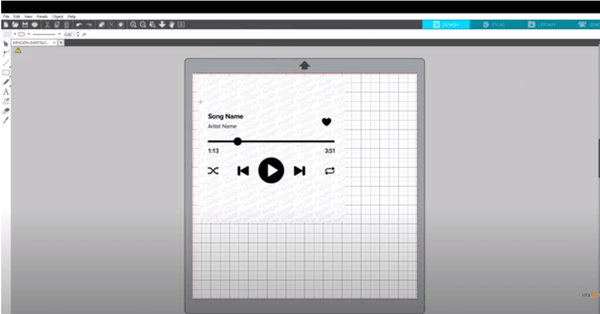

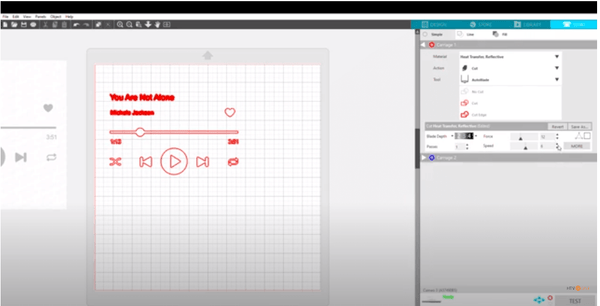

Before starting, prepare your design using graphic design software or choose from existing templates. Ensure the design is compatible with the size and shape of your desired stickers.

Step 2: Printer Setup

Ensure that you have a sublimation printer specifically designed for sublimation printing. Install the necessary sublimation ink cartridges or tanks and ensure your printer is calibrated correctly. This ensures optimal color reproduction and performance.

Step 3: Paper Loading

Load the sublimation sticker paper into the printer's paper tray. It is essential to load the paper with the printable side facing up. Check the manufacturer's instructions for any specific recommendations on paper loading.

Step 4: Adjust Printer Settings

Access the printer settings on your computer and choose the appropriate options for sublimation sticker paper. Select the correct paper type as specified by the manufacturer. Adjust print quality, color settings, and paper size to meet your requirements.

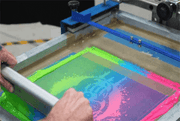

Step 5: Printing

With your design ready and printer settings adjusted, proceed to print your design onto the sublimation sticker paper. Set your printer to print at the highest quality possible to achieve vibrant and detailed results.

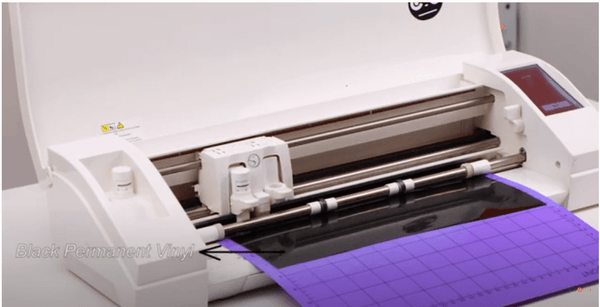

Step 6: Cutting

Once the printing is over, remove the printed sublimation sticker paper from the printer. Use scissors, a paper trimmer, or a cutting machine to print the stickers according to your desired shape and size. Take your time to ensure clean and precise cuts.

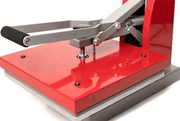

Step 7: Heat Press Preparation

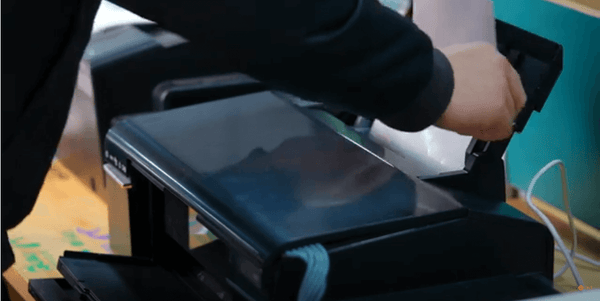

Preheat your heat press machine to the recommended temperature for sublimation. Consult the instructions the sublimation sticker paper manufacturer provided for the appropriate temperature and time settings. It is vital to follow these guidelines to achieve the best results.

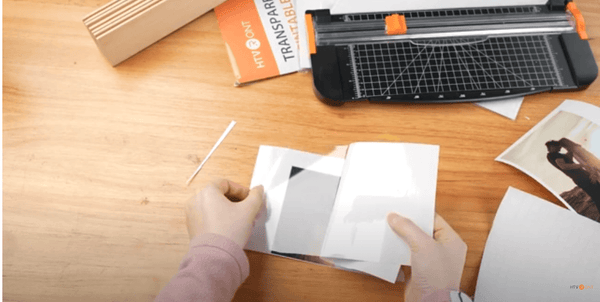

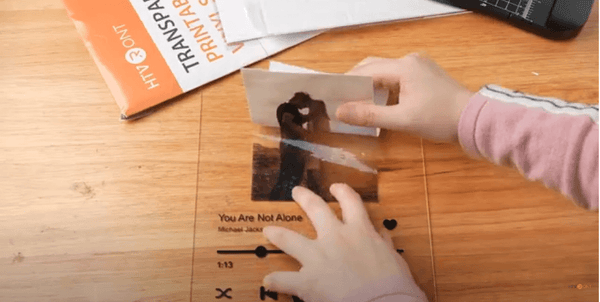

Step 8: Application

Place the cut-out sublimation stickers onto the desired substrate. Sublimation sticker paper is typically used on polyester fabrics or surfaces coated with a polyester layer. The stickers should be in the correct position without any protective backing.

Step 9: Heat Transfer

Once the stickers are in place, apply heat and pressure using the preheated heat press machine. Follow the manufacturer's instructions for the recommended time and pressure settings. The combination of heat and pressure will allow the sublimation ink to transfer from the paper onto the substrate.

Step 10: Cooling and Finalization

After the designated time has elapsed, carefully remove the substrate from the heat press machine. Allow the sublimation stickers to cool completely. This cooling process is necessary for the ink to fully set and adhere to the surface, ensuring a durable and long-lasting result.

So, with the above steps, now you can answer, "Can you sublimate on sticker paper?"

Part 3: Best Sublimation Sticker Paper Recommendations

When it comes to sublimation sticker paper, there are several excellent options available on the market. Here are three highly recommended brands:

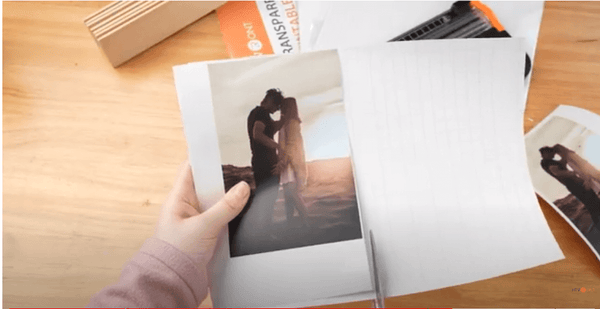

The remarkable quality of HTVRONT makes it the best sublimation sticker paper. It can achieve exceptional results with an ultra-high transfer rate of over 98%, ensuring less ink consumption and cost-efficiency for your creations.

HTVRONT offers affordable yet high-quality sublimation vinyl sticker paper in sizes like 8.5x14 inches and 8.5x11 inches, weighing 125g and 105g, respectively.

It is the go-to choice for both beginners and experienced sublimation enthusiasts. Elevate your sublimation projects with HTVRONT and witness the difference in quality and performance.

General reviews: 4.5/5

Specification:

- PACKAGE DIMENSIONS:14.48 X 8.78 X 1.34 Inches

- PACKAGE INCLUDES: Sublimation Paper 8.5x14 Inch - 200 Sheets

Price: Approximately $0.12 per count.

Forever Subli-Flex 202 is a versatile sublimation paper suitable for various applications, including stickers. It is compatible with both sublimation and transfer printing methods and offers excellent color vibrancy and durability.

General reviews: 3.6/5

Specification:

- Sublimation Paper 8.5x11 Inch - 10 Sheets

Price: Approximately $1.84 per count.

TexPrint is a popular choice for sublimation printing, including sticker production. It offers quick-drying properties and exceptional color transfer designed for use with sublimation inks. The paper is available in various sizes and sheet quantities to suit your needs.

General reviews: 4.8/5

Specification:

- Sublimation Paper 8.5x14 Inch - 110 Sheets

Price: Approximately $0.30 per count.

Part 4: Summary and FAQs

Thus, now you have the information on selecting and utilizing sublimation sticker paper. We also discussed the differences between sublimation vinyl sticker paper and sticker paper, along with step-by-step instructions on using sublimation paper.

Lastly, we highly recommend you experience the brilliance of vibrant colors, exquisite details, and stunningly decorated images with HTVFRONT. This premium paper ensures outstanding quality and exceptional results, allowing you to unleash your creativity like never before. Whether you're working on crafts, designs, or personalized items, HTVRONT transfer sublimation paper is the perfect choice to achieve stunning and professional-looking outcomes. Embrace the world of vibrant possibilities and elevate your creations to the next level with HTVRONT.

FAQs

Q1: How does sublimation sticker paper differ from regular sticker paper?

A: Sublimation sticker paper differs from regular sticker paper in its printing process and durability. Sublimation sticker paper is specifically designed for sublimation printing, which involves using sublimation inks and heat to transfer vibrant colors onto polyester or polyester-coated materials. The sublimation process results in durable, fade-resistant, and water-resistant stickers. On the other hand, you can print regular sticker paper with various printers using standard ink or toner, but with a lesser level of durability and color vibrancy than sublimation sticker paper.

Q2: What factors to consider when choosing sublimation sticker paper?

A: When choosing sublimation sticker paper, consider compatibility with your sublimation printer and inks. Look for a paper that offers vibrant color reproduction and high ink absorption. Durability is crucial, so opt for fade-resistant, water-resistant, and scratch-resistant paper. The size and quantity of sheets per pack should also align with your printing needs. Additionally, ensure the paper suits the specific substrates to which you intend to apply the stickers.

![[Starter Kit] Auto Heat Press Machine 15" x 15" 110V + Starter Kit Bundle](http://www.htvront.com/cdn/shop/files/20240425-170634_385x.jpg?v=1714036345)

![[Premium Bundle] Auto Heat Press Machine 15" x 15" 110V + 20 rolls HTV Bundle 12“x3ft + Mini 2 Heat Press Machine + Random Sublimation & HTV Bundle ≥ $180](http://www.htvront.com/cdn/shop/files/1UK_4_22c12b1b-12dd-4105-ac25-93e2faae6a8c_385x.jpg?v=1713863580)